Published on Jun 05, 2023

Cryocar

MThe importance of cars in the present world is increasing day by day. There are various factors that influence the choice of the car. These include performance, fuel, pollution etc. As the prices for fuels are increasing and the availability is decreasing we have to go for alternative choice.

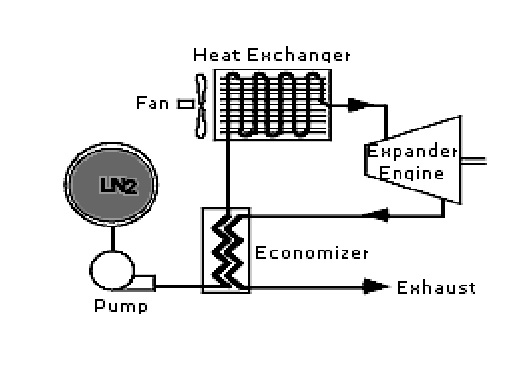

Here an automotive propulsion concept is presented which utilizes liquid nitrogen as the working fluid for an open Rankine cycle. When the only heat input to the engine is supplied by ambient heat exchangers, an automobile can readily be propelled while satisfying stringent tailpipe emission standards. Nitrogen propulsive systems can provide automotive ranges of nearly 400 kilometers in the zero emission mode, with lower operating costs than those of the electric vehicles currently being considered for mass production. In geographical regions that allow ultra low emission vehicles, the range and performance of the liquid nitrogen automobile can be significantly extended by the addition of a small efficient burner.

History

Researchers at the University of Washington are developing a new zero-emission automobile propulsion concept that uses liquid nitrogen as the fuel. The principle of operation is like that of a steam engine, except there is no combustion involved. Instead, liquid nitrogen at –320° F (–196° C) is pressurized and then vaporized in a heat exchanger by the ambient temperature of the surrounding air. This heat exchanger is like the radiator of a car but instead of using air to cool water, it uses air to heat and boil liquid nitrogen. The resulting high-pressure nitrogen gas is fed to an engine that operates like a reciprocating steam engine, converting pressure to mechanical power. The only exhaust is nitrogen, which is the major constituent of our atmosphere.

The LN2000 is an operating proof-of-concept test vehicle, a converted 1984 Grumman-Olson Kubvan mail delivery van. Applying LN2 as a portable thermal storage medium to propel both commuter and fleet vehicles appears to be an attractive means to meeting the ZEV regulations soon to be implemented. Pressurizing the working fluid while it is at cryogenic temperatures, heating it up with ambient air, and expanding it in reciprocating engines is a straightforward approach for powering pollution free vehicles. Ambient heat exchangers that will not suffer extreme icing will have to be developed to enable wide utility of this propulsion system. Since the expansion engine operates at sub-ambient temperatures, the potential for attaining quasi-isothermal operation appears promising.

Economizer

A preheater, called an economizer, uses leftover heat in the engine's exhaust to preheat the liquid nitrogen before it enters the heat exchanger. Hence the economizer acts as a heat exchanger between the incoming liquid nitrogen and the exhaust gas which is left out. This is similar to the preheating process which is done in compressors. Hence with the use of the economizer, the efficiency can be improved. The design of this heat exchanger is such as to prevent frost formation on its outer surfaces.

Expander

The maximum work output of the LN2 engine results from an isothermal expansion stroke. Achieving isothermal expansion will be a challenge, because the amount of heat addition required during the expansion process is nearly that required to superheat the pressurized LN2 prior to injection. Thus, engines having expansion chambers with high surface-to-volume ratios are favored for this application. Rotary expanders such as the Wankel may also be well suited. A secondary fluid could be circulated through the engine block to help keep the cylinder walls as warm as possible. Multiple expansions and reheats can also be used although they require more complicated machinery.

Technical Issues

Range extension and performance enhancement can be realized by heating the LN2 to above ambient temperatures with the combustion of a relatively low pollution fuel such as ethanol or natural gas. By increasing the gaseous N2 temperature to 500 K, the specific work at 4 MPa for the adiabatic engine is increased by 60% to make it nearly the same as the work from an isothermal expansion engine operating at 300 K. In this particular propulsive cycle an extra superheat of 200°C results in only a 30% increase in specific power. Thus the advantage of operating above ambient temperature depends, in part, on how isothermal the expansion process can be made to be.

There is also the intriguing possibility of storing energy for boosting power or extending range by applying a medium that undergoes a phase change to the final superheater segment of the heat exchanger system. Ideally the phase change material would be slowly "recharged" as it absorbs heat from the atmosphere while the vehicle is parked and during cruise when peaking power is not required. Fast recharging with electric heaters may also be considered. We recognize that this added complexity must compete in mass and compactness with the alternative of just carrying more LN2.

Related Seminar Topics

- 3d Machine Vision Systems

- Aerodynamics of Race Car

- Aeroplane Propulsion System

- Aerodynamics of Race Car

- Air Muscles

- Air Powered Cars